Китайський постачальник Китайська фабрика прес-форм. Деталі інструментів для лиття під тиском. Подвійна прес-форма для лиття під тиском для побутових/електронних виробів з ABS/PC/POM у формувальній компанії

Деталі продукту

Швидкі та чудові ціни, поінформовані консультанти, які допоможуть вам вибрати правильний продукт, який відповідає всім вашим вимогам, короткий час виготовлення, відповідальне управління високою якістю та унікальні послуги з оплати та доставки для китайського постачальника China Mold Factory Custom Design Die Casting Tooling Parts Double Прес-форма для лиття пластику для побутових/електронних виробів з ABS/PC/POM у формувальній компанії. Ми з нетерпінням чекаємо на співпрацю з усіма клієнтами з країни та за кордоном.Крім того, задоволеність клієнтів є нашим вічним прагненням.

Швидкі та відмінні ціни, поінформовані консультанти, які допоможуть вам вибрати правильний продукт, який відповідає всім вашим вимогам, короткий час виготовлення, відповідальне управління якістю вищого рівня та унікальні послуги з оплати та доставки для , Ми підтверджуємо громадськості, співпрацю, взаємовигідну ситуацію як наш принцип, дотримуйтесь філософії заробляти на життя якістю, продовжувати розвиватися чесністю, щиро сподіватися на побудову хороших стосунків із все більшою кількістю клієнтів і друзів, щоб досягти безпрограшної ситуації та спільного процвітання.

Аналіз проекту:

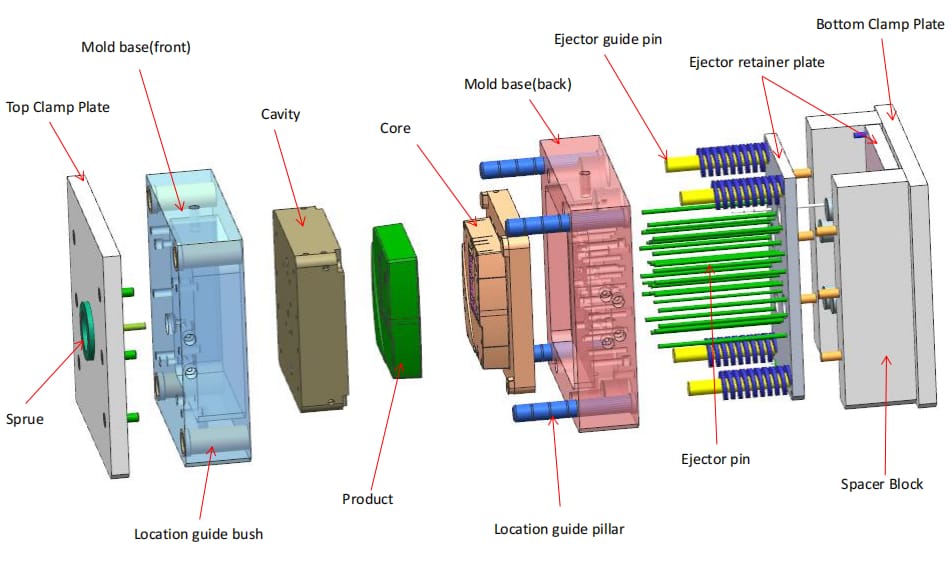

Отримавши 3D-креслення та вимоги від клієнтів, наша команда інженерів оцінить її конструкції та розміри, щоб обговорити та розглянути, як спроектувати прес-форму (наприклад, затвор для ін’єкцій, штифти, кут тяги тощо).

Процес виробництва:

1. Затиск:

Інструмент закривається, що означає початок циклу лиття під тиском.

2. Ін'єкція:

Полімерні гранули спочатку висушуються і поміщаються в бункер, потім вони подаються в бочку, де вони одночасно нагріваються, змішуються і переміщуються до прес-форми шнеком зі змінним кроком.Геометрія шнека та стовбура оптимізовано, щоб допомогти створити тиск до потрібного рівня та розплавити матеріал.

3. Охолодження:

Після заповнення порожнини інструменту смолі необхідно дати охолонути.Вода проходить через інструмент для підтримки сталої температури, поки матеріал твердне.

4. Викид

Коли матеріал охолоджується, він знову застигає і приймає форму форми.Нарешті, форма відкривається, і тверда частина виштовхується виштовхуючими штифтами.Потім форма закривається, і процес повторюється.

5. Пакет

Готова продукція буде упакована в поліетиленовий пакет і покладена в коробки.Спеціальні вимоги до упаковки також можуть бути налаштовані відповідно до потреб клієнтів. Таким чином, кожен продукт буде доставлено в хорошому стані. Швидкі та відмінні ціни, поінформовані консультанти, які допоможуть вам вибрати правильний продукт, який відповідає всім вашим вимогам, коротке виготовлення час, відповідальне управління високою якістю та унікальні послуги для оплати та доставки справ для Китаю Постачальник China Mold Factory Індивідуальний дизайн Деталі інструментів для лиття під тиском Подвійна прес-форма для лиття під тиском для побутових/електронних виробів з ABS/PC/POM у Формовій компанії, ми з нетерпінням чекаємо співпрацювати з усіма клієнтами вдома та за кордоном.Крім того, задоволеність клієнтів є нашим вічним прагненням.

Китайський постачальник китайських прес-форм і пластикових форм для лиття під тиском, ми підтверджуємо громадськості співпрацю, взаємовигідну ситуацію як наш принцип, дотримуємось філософії заробляти на життя якістю, продовжувати розвиватися чесністю, щиро сподіваємося налагодити хороші стосунки з більшою кількістю і більше клієнтів і друзів, щоб досягти безпрограшної ситуації та спільного процвітання.